在制药,精细化工等生产中,常常会有很多液相或汽相混合物中需要分离或提纯,精馏技术便成为应用广和规模大的传质分离过程。今天,这篇文章讲讲精馏的种类以及举例说明其在实际生产运用中的工艺流程。

精馏技术是根据在一定压力下通过多次部分气化和多次部分冷凝使得混合液得以分离,以分别获得接近纯态的部分的过程。工业生产中的精馏过程是在精馏塔中将部分气化过程和部分冷凝过程有机结合起来的过程。

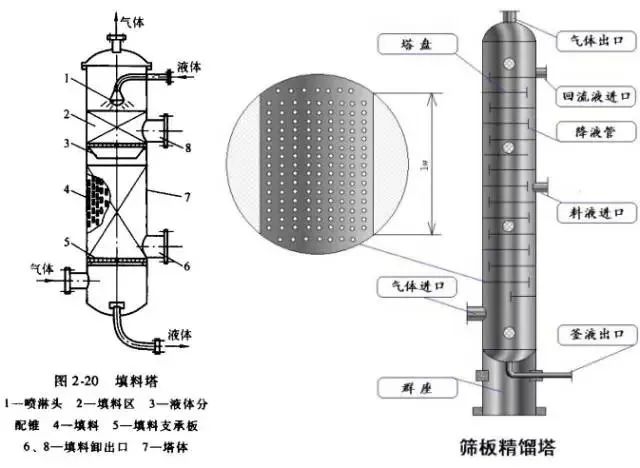

精馏操作分为连续操作和间歇操作,所用设备大同小异。主要为精馏塔、冷凝器、再沸器。用于精馏的塔设备有板式塔和填料塔,常用的是板式塔。

精馏技术的分类及实际生产中工艺流程举例:

此精馏方法通过加入某一组分(称为夹带剂)去与被分离物系中的一个或几个组分形成共沸物或是破坏原物料组分间可能存在的共沸物的方式达到分离效果,可分为萃取精馏、共沸精馏和加盐精馏。

1、共沸精馏

共沸精馏是利用混合物中的物质能形成共沸物的性质来实现分离的过程。共沸精馏是多组分(至少是三组分)非理想溶液的精馏。

根据所形成的共沸物能否分离为不互溶的两个液相,分为均相共沸精馏和非均相共沸精馏。

塔顶产品为非均相共沸物的流程:▼

乙醇-水共沸混合物和夹带剂苯加入 A 塔,塔底得到纯乙醇。

塔顶得到水、乙醇和苯的三元共沸混合物,冷凝后进入分相器,在分相器中形成两个液层,上层富苯,下层富乙醇。

富苯层回流至 A 塔补充夹带剂,富乙醇层进入 B 塔,塔顶得到苯-乙醇共沸物以回收苯,塔底得到乙醇和水的混合物进入 C 塔。

C 塔顶为乙醇-水共沸物,塔底为纯水。

通过此流程可以完成乙醇、水的分离。

塔顶产品为均相共沸物的流程:▼

这一类共沸精馏流程比较复杂。图 1.9 所示为用甲醇作夹带剂,从沸点接近的烷烃中分离甲苯的流程。

A 塔塔顶产物(甲醇-烷烃共沸物)冷凝后不分层,共沸剂的回收不能利用简单的分层法,而需将塔顶产物通入萃取塔 B 中,从塔顶加入水将甲苯萃取出来。

萃取塔顶部得到轻相烷烃,底部出来的甲醇-水溶液在普通精馏塔中可分离得到甲醇和水。

A 塔塔底产物进入 D 塔,D 塔底得到甲苯,塔顶产品部分回流,部分返回 A 塔继续使用。

2、萃取精馏

萃取精馏是通过向待分离组分中加入萃取剂(第三方组分)以显着改变待分离组分的相对挥发度来实现分离的过程。

在苯精制工艺中,将经过焦化预处理的苯产品引入萃取精馏法除烷烃和烯烃的阶段,具体过程如图2-2所示:将预处理后的原料加入萃取精馏塔中部,从萃取精馏塔顶部加入萃取剂,从塔底部排出饱和溶剂(其主要成分为萃取剂、苯和噻吩),从塔顶排出萃余液(含有较多杂质的混合物)。

之后将饱和溶剂送进溶剂回收塔进行溶剂回收,回收后的溶剂送进萃取塔精馏塔顶部进行循环使用。

3、加盐萃取精馏

加盐萃取精馏是用固体盐做萃取剂或向萃取剂中加入固体盐来增加萃取剂分离性能的分离过程。

进料 ( 甲醇-甲苯共沸物 ) 与从甲苯回收塔 ( T2 ) 顶部蒸出的甲醇和甲苯的近沸物混合后,由萃取塔 ( T1 ) 底部进入,从甲醇回收塔 ( T3 ) 底部返回的加盐萃取剂经冷却器( E5 ) 冷却降温至 35 ℃ 后进入 T1 塔顶部,在 T1 塔内完成逆流萃取。

T1 塔顶部的萃余相进入甲苯回收塔 ( T2 ) ,在塔底得到合格的甲苯产品,塔顶物料返回至 T1 塔底部。

T1 塔 底 部 的 萃 取 相 进 入 甲 醇 回 收 塔 ( T3 ) ,在塔顶得到合格的甲醇产品,塔底盐水冷却后返回至 T1 塔顶部。

复合精馏是将形式多样的精馏形式进行耦合以达到强化传质过程和简化工艺的目的。

比较典型的有反应精馏、吸附精馏、结晶精馏、和膜精馏等。

1、反应精馏

反应精馏是将反应过程和精馏分离有机结合在一起在同一设备中进行的一种耦合过程。反应精馏只适用于化学反应和精馏过程在同样温度和压力范围内进行的工艺过程。

以常温常压下典型的液相可逆反应A+B⇌C+D为例,对反应精馏的工艺流程作一介绍,A,B,C,D 4种物质的挥发度由大到小的顺序为C, A ,B,D其中目标产物为D。

由图(b)可见,采用反应精馏技术,原料A和B分别从反应段的下方和上方进入反应精馏塔,在反应段充分接触反应,目的产物和反应物得到了及时的分离。

2、吸附精馏

吸附蒸馏是综合利用了吸附分离因数高、产品纯度高和能耗低的特点和蒸馏易于连续生产、处理能力大的优点而开发出的一种新型的强化精馏过程。

工艺流程图1-6为用乙二醇作载液和4A分子筛作吸附剂共同组成的浆液,对叔丁醇-水共沸物的吸附蒸馏分离的工艺过程。

稀叔丁醇水溶液连续输入吸附蒸馏塔的下部,同时一定量的乙二醇与 4A 分子筛形成浆液从吸附蒸馏塔的上部连续输入。

由于乙二醇的沸点高于水,水的沸点又高于叔丁醇,于是在吸附蒸馏塔中,由于蒸馏作用和4A 分子筛的吸附作用,使得叔丁醇向塔顶富集,同时水和乙二醇与 4A 分子筛形成的料浆也同时流向塔底,水一部分留在载液中,另一部分被 4A 分子筛吸附。

吸附蒸馏塔塔釜液随后送入蒸馏脱附塔,由于蒸馏作用和 4A 分子筛的脱附作用,使得水向蒸馏脱附塔中塔顶富集,同时 4A 分子筛中的水被解吸,乙二醇载液与4A 分子筛组成的料浆流向塔釜,最后回流到吸附蒸馏塔还可以继续使用。

3、结晶精馏

结晶精馏是将结晶和精馏两种方式联合在一起的工艺,既可以得到高纯度的产品又强化了精馏工艺过程。

结晶精馏用于分离MDI的同分异构体,MDI存在2,4’-MDI4,4’-MDI,2,2’-MDI 三种同分异构体,其中MDI-100是指含4,4’-MDI 纯度达99%以上的MDI,MDI-50 指2、4’-MDI和4,4’-MDI的混合物。

本流程将物料首先进入熔融结晶器, 结晶器采用悬浮结晶方式 ,使 4, 4′-MDI部分结晶。

分离后 , 晶体经多次洗涤为 MDI-100产品, 洗涤液回流到结晶器重新结晶。母液经加热后进入真空精馏装置 , 控制回流比及塔顶采出量 ,使 2,4′-MDI侧线采出口中 2, 4′-MDI的质量分数约 50%, 作为 MDI-50产品。

4,4′-MDI侧线采出口中 2,4′-MDI含量为 10%, 并作为回流与进料混合后进入结晶器重新结晶。

非常规条件是一个相对概念,相对通常的精馏过程而言,非常规条件下的精馏是指操作参数(如操作温度、压力等)在较为恶劣的条件下进行,或是分离对象或获得产品质量(纯度)要求很高等。

1、分子精馏

分子精馏原理:不同的分子有着不同的分子有效直径, 故它们的平均自由程也不相同。 分子蒸馏技术是利用不同物质分子受热蒸发逸出液面后的平均自由程大小的不同来实现分离提纯的。

具体方法是在液面上方大于重分子平均自由程而小于轻分子平均自由程处设置一冷凝面, 使得重分子达不到冷凝面而返回液面, 保持原有的平衡;而轻分子不断地在冷凝面上冷凝, 从而破坏了轻分子的动态平衡, 结果使混合液中的轻分子不断从液相逸出, 最终达到分离的目的。

具体过程(见下图 )。▼

2、真空精馏

真空精馏是指精馏过程在真空下进行的操作,常用于高沸点物质或热敏物质的分离与提纯。

真空精馏过程在精细化学品的生产过程中有着广泛的应用。比如:含有杂质的硒渣经过两次蒸馏最终得到纯度较高的硒。

QQ:1535977408

QQ:1535977408 邮箱:1064918590@qq.com

邮箱:1064918590@qq.com 传真: 86-0572-5682616

传真: 86-0572-5682616 地址:杭州市九环路9号大学科技园B座5楼

地址:杭州市九环路9号大学科技园B座5楼

扫一扫 微信咨询

©2025 杭州科力化工设备有限公司 版权所有 备案号:浙ICP备05046274号-3 技术支持:制药网 Sitemap.xml 总访问量:409988 管理登陆